White Papers

Evaluation of Soil Disturbance due to Sonic Drilling using Instrumentation and Cone Penetration Test Measurements

UC Davis Electronic Theses & Dissertations | Green, KC

Sonic drilling is an efficient and versatile drilling technique used to continuously core soils and soft rock, and it is increasingly used for geotechnical site characterization. During sonic drilling, the sonic head and attached drill string are vibrated to advance the drill string into the subsurface. These vibrations are transmitted to and propagated through the surrounding soil, causing some amount of disturbance to the soil. However, the magnitude of disturbance as a function of the zone of influence (radial and vertical distance) and soil type has not yet been quantified. This thesis presents the results of two field studies that quantify the sonic induced soil disturbance with an array of installed instrumentation. In addition, as an indicator of the possible disturbance to in-situ tests or soil sampling below the bit, changes in baseline measured CPT parameters are evaluated when a CPT sounding is performed into soils immediately below the sonic casing.

Drilling in Earth Embankment Dams and Levees

U.S. Army Corps of Engineers | Washington DC

This regulation establishes policy and requirements and provides guidance for drilling in dam and levee earth embankments and/or their earth and rock foundations. The primary purpose of this regulation is to prevent damage to embankments and their foundations from hydraulic fracturing, erosion, filter/drain contamination, heave, or other mechanisms during drilling operations, sampling, in-situ testing, grouting, instrumentation installation, borehole completion, and borehole abandonment.

Pore pressure response during high frequency sonic drilling and SPT sampling in liquefiable sand

F J Wentz | Wentz-Pacific Ltd, Napier, NZ

The potential for systematic variations in SPT N –values between mud rotary and sonic drilling methods has been the focus of a pilot investigation at a site that exhibited extensive liquefaction during the 22 February 2011 M 6.3 Christchurch Earthquake. In an attempt to quantify the impact of drilling methods on N-values, 2 pairs of closely-spaced sonic and mud rotary boreholes were advanced in deposits of predominantly silty sand and sand silt with SPT tests at 1.5 m intervals.

Resonant Sonic Drilling: History, Progress and Advances in Environmental Restoration Programs

Westinghouse Hanford Company, U.S.Department of Energy, and Water Development Corporation

ResonantSonic™ drilling is being used in the environmental industry to drill faster, cheaper, and safer than conventional drilling methodologies. ResonantSonic is a registered service mark of the Water Development Corporation, Woodland, California. The ResonantSonic drilling method, requires no mud, air or water for rapid penetration through geologic materials ranging from rock and clay to sand and boulders. The specialized drill head imparts high frequency vibrations into a steel drill pipe creating a drilling action which allows the retrieval of continuous, undisturbed cores. An added benefit is that the method can be used for angle drilling.

Sonic Core NAPL FLUTe Procedure

Flexible Liner Underground Technologies | Santa Fe, New Mexico

The NAPL FLUTe system was first developed for installing color reactive liners in holes formed by cone penetrometers or Geoprobe type push rod methods. However, the utility of the color reactive cover developed by FLUTe has been extended to installations via the FLUTe everting liner system for stable holes (e.g., core holes in rock) and to mapping of NAPLs and DNAPLs in core obtained via sonic drilling methods. This procedure is for the use of the NAPL FLUTe cover to map NAPLs in sonic drilling core.

Structural drilling using the high-frequency (sonic) rotary method

Jurij Šporin*, Željko Vukelić | Faculty of Natural Sciences and Engineering, Department of Geotechnology, Mining and Environment, Slovenia

In Slovenia, there is widespread use of structural drill- ing along with classical core drilling. Recently, however, the need has arisen for a highly effective core drilling method with the aid of which high-quality core might be obtained. In order to achieve this aim, one among several Slovenian companies dealing with geological surveying has decided to implement structural drilling using a high-frequency drilling method. The following article presents the theoretical foundations for such a high-frequency method, as well as the manner of its im- plementation. In the final part of the article, a practical comparison between the conventional and the high-fre- quency core drilling methods is also provided.

Industry Articles

TSI and Massenza create new benchmark in sonic drilling

To better meet the needs of the drilling sector North America’s Terra Sonic International is combining its sonic drilling knowledge with the hydraulic rig designs of Massenza to bring a new line of sonic drill rigs to the market. The first offering from this new partnership is the TSi 150CC-MM8

…

The Terra Sonic International and Massenza partnership underscores the international acceptance of sonic drilling in virtually every sub-market of the drilling industry. “Terra Sonic International is the most experienced manufacturer of sonic drill rigs in the world and the foremost in North America,” Azzoni says. “Europe’s growing demand for sonic has led to our partnership. Our customers will have access to the most powerful sonic drill heads and the highest quality and most reliable drilling rigs.”

Forging a new path deep in the river

Josh Kulla, Daily Journal of Commerce

For decades, observers have seen the city of Portland tackle projects to address aging, dilapidated infrastructure. One of the most important ones now taking place will be much less conspicuous.

The Willamette River Crossing Project is an estimated $88 million effort to build a seismically resilient water pipeline underneath the Willamette River and connect two large header pipes – one on each side. Those header pipes provide connections for six water pipelines across the river and act like a manifold for the city’s water supply system.

…

Right now, a crew from Holt Services of Vancouver, Washington, is taking soil samples from a variety of depths beneath the river. This work will guide engineers as they reconfigure the work needed to bore through the earth and place the new pipeline. All of this work is taking place under the watch of contractor James W. Fowler Co. of Dallas.

Painting an underground picture: Geotechnical field work helps inform planning, design and construction of Sound Transit projects.

Katie Metzger, The Platform, September 2020

With all of the uncertainty caused by COVID-19, it can be difficult to look 10 days into the future, let alone 10-plus years. But that’s exactly what Sound Transit is doing as we continue to study options for the future Link light rail extensions from downtown to West Seattle and Ballard.

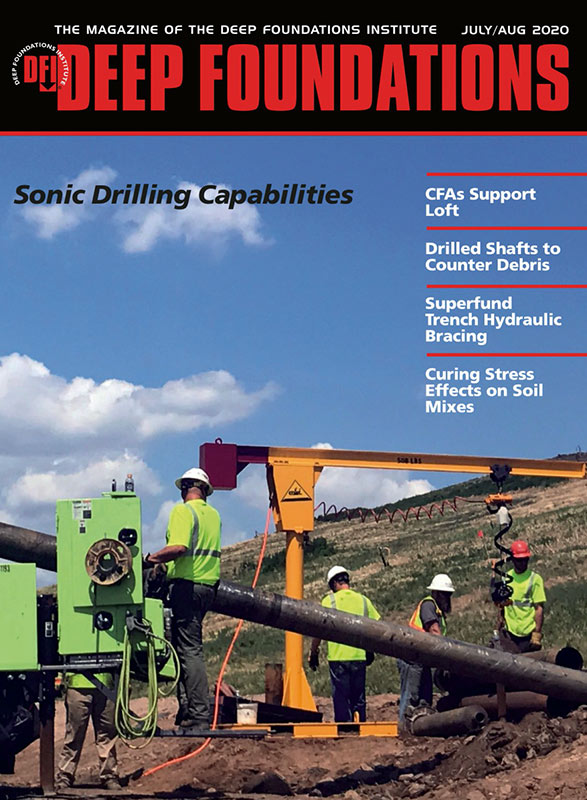

Sonic Drilling for Infrastructure Rehab

Deep Foundations, July/August 2020

Sonic drilling was initially developed primarily as an exploration tool for core sampling of unconsolidated materials. However, it has evolved quite a lot over the past few decades, and has gained considerable popularity in the infrastructure/geoconstruction market as a multifaceted drilling platform capable of providing a wide range of drilling solutions.

Making geothermal energy accessible

CNN, 2020

CNN’s Kelly Bowman reports on how Dandelion Energy is working to limit your carbon footprint

On The Upgrade

Mining Magazine, June 2016

Today’s cost-conscious mining houses and drilling contractors are asking themselves: to replace or to rebuild? Nia Kajastie looks into the options and what’s involved in drill-rig rebuilds

Riding with the tide

GeoDrilling International, May 2015

A geotechnical driller in deep water takes advantage of a combination of diamond coring and sonic drilling

A Parting Shot

National Driller, October 2014

Steven Widincamp, chief of the U.S. Army Corps of Engineers Savannah District’s exploration unit, takes a turn with the district’s new TerraSonic drill rig. The rig — the first of its kind for USACE — will go to work in subsurface and geotechnical investigation projects.

Doubling the rigs cuts the Time in half

Engineering News-Record, May 2015

Terra Sonic International (TSI) recently performed

a large environmental site assessment project for Ecotech Environmental Services (Pompano Beach, Fla.). The project involved the installation of 25 monitoring wells covering five properties in Pensacola, Fla.

Sonic Drilling Top Tips, Benefits and Rigs

GeoDrilling International, June 2014

At a time when safety, cost-effectiveness, efficiency and environmental stewardship are in demand, sonic drilling presents itself as a beneficial solution for many drilling applications. Terra Sonic International details the seven primary benefits that sonic drilling offers

Why sonic drilling Is Ideal For underground Applications

Engineering News-Record, February 2015

If it were certain what conditions existed underground, there would be less need for geotechnical or investigative drilling.